The First Sea Trial

By Dermot Tynan, about 12 years ago.

On September 1st, we launched the hull in Aughinish bay, without sails, rudder or electronics. The purpose was to see how the hull performed in open water, with the keel attached. As the keel wasn't properly attached or sealed in place, the main compartment flooded with water, but as the compartments are individually water-tight, this wasn't an issue. It did lower the boat in the water somewhat, but not to any significant degree.

Latest on the hull

By Dermot Tynan, about 12 years ago.

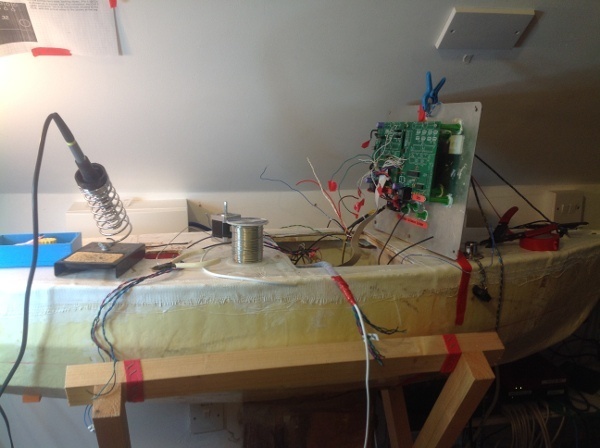

Here's a quick sneak picture of the hull with the wiring harness complete and the decks sealed in place.

The keel is still only temporarily installed so the main compartment is again flooding with sea water. The bow is still slightly down in comparison to the stern, but this is mostly due to the flooded compartment. Also, the keel still hasn't been moved back, yet. That will happen this week.

The rubber hits the road. Sort of.

By Dermot Tynan, almost 12 years ago.

Due to other, exciting distractions (which I will mention in a later post), I haven't had a chance to keep the blog up to date. Still, work progresses on the boat, and that's the important part. Last month, with the keel now in its new position about 30mm further back along the hull, and sealed into place, it was time to add the electronics board.

Hull 002

By Dermot Tynan, over 9 years ago.

I have discussed the hull construction process in earlier posts, which you can find via the above search bar. To recap, you take the hull design and "loft" the shape of each section or bulkhead, from the drawing. You then cut this out of 6mm marine ply (or equivalent), mount each of the stations onto a strongback, and now you have something which forms the shape.

I also need to add a keelson to the picture. A keelson is a long, keel-like piece of wood which runs from stem to stern, connecting the bulkheads. I cut one already but it turned out to be too short due to a miscalculation on my part. Generally I cut a thin (about 2cm wide) outline of the keel of the boat, from a sheet of ply.

Robotic Sailboats and Airborne Viruses

By Dermot Tynan, almost 5 years ago.

One would think that a global pandemic would be a great opportunity to hunker down and get some work done on one or other robotic sailboats. Unfortunately, this hasn't turned out to be the case. I am still knee-deep in hull work on boat #2, the main entrant. However, due to lockdown restrictions, I can't physically access the hull and so it has spent most of the last twelve months, waiting for more sanding and filling (side note: never let anyone tell you that you can "fix it at the sanding/filling stage"). But it's not all bad news. The lockdown has been good for boat #1, the test vessel.

Upcoming Missions

- Galway Bay Loop, Waiting for Vessel Availability

Search

Recent Posts

- May 2023 (1 post)

- April 2023 (1 post)

- March 2023 (1 post)

- February 2023 (2 posts)

- March 2022 (3 posts)

- March 2021 (1 post)

- August 2020 (1 post)

- May 2019 (1 post)

- April 2018 (1 post)

- November 2017 (1 post)

- April 2017 (1 post)

- November 2016 (1 post)

- September 2016 (1 post)

- August 2016 (1 post)

- January 2014 (2 posts)

- October 2013 (7 posts)

- September 2013 (1 post)

- August 2013 (3 posts)

- June 2013 (3 posts)

- May 2013 (4 posts)

- April 2013 (3 posts)

- March 2013 (9 posts)

- February 2013 (8 posts)