The Marvel of 3D Printing...

By Dermot Tynan, over 12 years ago.

So, while debating the different merits (or otherwise) of various mounting solutions, someone suggested using a 3D printer to actually print the housing for the masthead wind direction indicator. The more I thought about that plan, the better I liked it. As it happens, 091 Labs in Galway have a working 3D printer, from the Mendel90 family. What's more, they are trying to get a 3D printing service off the ground! I wasn't customer number one, but I was probably pretty close.

I love it when a Plan comes together...

By Dermot Tynan, over 12 years ago.

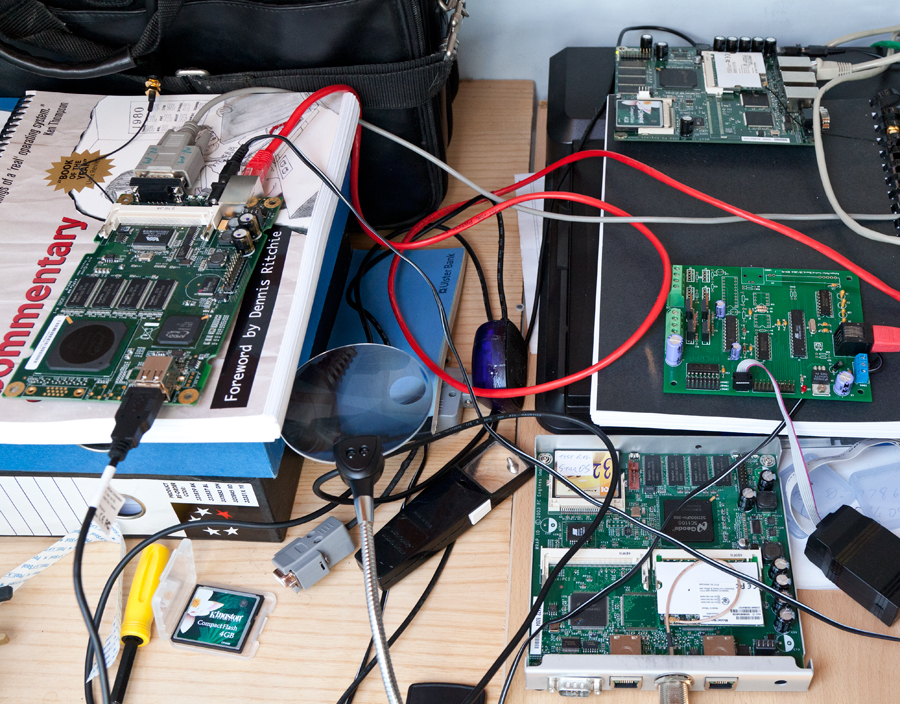

The new ALIX board has arrived. It's to the left of the picture, sitting on top of a copy of the Lyon's Notes (which is appropriate). It's running my custom version of NanoBSD quite nicely, and can see the GPS without any difficulty. The GPS unit is a BU-353 unit (the USB version) which is out of the shot. It's attached to the window, and gazing at the man-made stars. To give a breakdown of what's in that photograph, the ALIX is on the left. In the USB port is the GPS, the RS-232 cable at the top of the board is communicating with my development machine (running FreeBSD). The red CAT5 cable is connecting the board to the "house network." The Atheros CM9 radio is a miniPCI card mounted on the underside of the board. It works on 5.8GHz and on 2.4GHz. In this case, I'm using 5.8GHz because (apparently) it has better cross-water characteristics and the band isn't as crowded. The mini coax cable is at the top-left of the picture, connected to a short, 9dBi antenna. You can also see a 12v cable with barrel plug. At the top-right of the picture is a WRAP board, also developed by PC Engines. It was being used as a testbed for the operating system, but that is no longer needed thanks to the ALIX.

Wind Direction Indicator

By Dermot Tynan, over 12 years ago.

Now that the hull is looking solid, it's time to start thinking again about the wind direction indicator. It is possible to detect wind speed by using an ultrasonic sensor and receiver, and measuring the delay between the two. You need to account for temperature changes and gusts can cause issues, but it is fairly reliable and has no moving parts. Generally, you use two transducers offset by a distance of perhaps 20cm for the North/South computation, and another pair in the East/West direction. I think if we were using a larger hull, such as a 4m boat, this would be a good plan. But, for the 2.4m (or the 1.2m) boat, it's just too big and awkward. Also, this jury is undecided about how well they would work, over the long haul.

Hull 001 is almost ready for fibreglass

By Dermot Tynan, over 12 years ago.

After applying 3/32" balsa wood to the bulkheads and transom, the hull is starting to look like a real boat!

You can clearly see the deck support frames now. They are 6mm below the sheer line, to allow for 6mm exterior (or marine) ply deck pieces. But first, the balsa needs to be sanded and patched a bit. Also, the 3 or 4 layers of chopped strand matt need to be applied. When it is finished, the balsa wood will be completely enclosed in fibreglass. This is a standard "sandwich" construction. The balsa adds a layer of strength (believe it or not!) to the two layers of glass either side. It is similar to the central section of an I-beam or girder in that it separates the two outer layers and means that the bend radius is increased. Or at least, that's my understanding of it...

Upcoming Missions

- Galway Bay Loop, Waiting for Vessel Availability

Search

Recent Posts

- May 2023 (1 post)

- April 2023 (1 post)

- March 2023 (1 post)

- February 2023 (2 posts)

- March 2022 (3 posts)

- March 2021 (1 post)

- August 2020 (1 post)

- May 2019 (1 post)

- April 2018 (1 post)

- November 2017 (1 post)

- April 2017 (1 post)

- November 2016 (1 post)

- September 2016 (1 post)

- August 2016 (1 post)

- January 2014 (2 posts)

- October 2013 (7 posts)

- September 2013 (1 post)

- August 2013 (3 posts)

- June 2013 (3 posts)

- May 2013 (4 posts)

- April 2013 (3 posts)

- March 2013 (9 posts)

- February 2013 (8 posts)