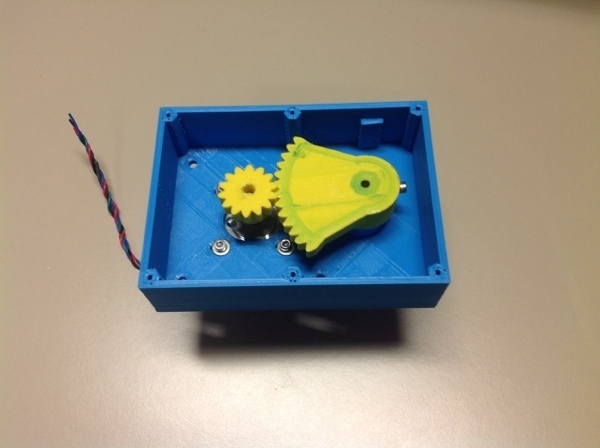

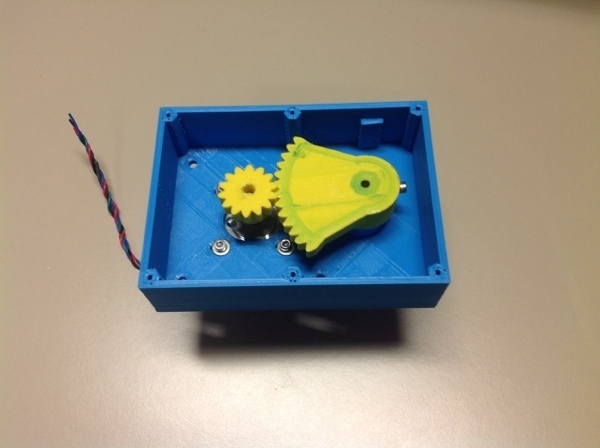

Rudder box with gears

By Dermot Tynan, over 12 years ago.

This photograph is of the new rudder box with a NEMA17 stepper (underneath) and the two gears. The smaller gear is on the stepper and the larger, quarter gear will be clamped to the rudder shaft. It's a 4:1 ratio and the rudder gear is 90 degrees so one complete turn of the stepper will bring the rudder from end to end. That's plus or minus 100 steps.

The new rudder

By Dermot Tynan, over 12 years ago.

Thanks go to Colman Corrigan for designing and building the keel and rudder. The keel follows the traditional NACA shape, with a rounded leading-edge, tapering off to a narrow trailing edge. It is approximately a 6318 shape, with the maximum width being about 36% of the length of the cross-section. Overall, the keel is coming in at about 750mm from hull to the end of the bulb, and about 240mm from front to back. That's a 3:1 aspect ratio.

Rudder with filler.

By Dermot Tynan, over 12 years ago.

This is a quick photograph of the rudder stock once it was filled with a mixture of West System 405 microfibres and West System epoxy. I formed a basic mould out of wood, added "shrink wrap" to prevent the filler from sticking to the mould, dropped in the rudder stock frame (see below) and then poured in the filler. It took around a week to fully harden, and I will sand and paint the finished product.

Rudder Movement Test

By Dermot Tynan, over 8 years ago.

I have uploaded a video (to YouTube) of the rudder mechanism on Hull #1 working from end-stop to end-stop. (Excuse the video quality, I used my phone to record it.)

I connected an Arduino (Mega2560 if you want to know) and a SparkFun stepper controller to the stepper motor which drives the rudder. I wanted to exercise the tiller gears and the rudder shaft for a while. The video shows the rudder swinging from almost completely to Starboard, all the way back to Port.

Robotic Sailboats and Airborne Viruses

By Dermot Tynan, almost 5 years ago.

One would think that a global pandemic would be a great opportunity to hunker down and get some work done on one or other robotic sailboats. Unfortunately, this hasn't turned out to be the case. I am still knee-deep in hull work on boat #2, the main entrant. However, due to lockdown restrictions, I can't physically access the hull and so it has spent most of the last twelve months, waiting for more sanding and filling (side note: never let anyone tell you that you can "fix it at the sanding/filling stage"). But it's not all bad news. The lockdown has been good for boat #1, the test vessel.

Upcoming Missions

- Galway Bay Loop, Waiting for Vessel Availability

Search

Recent Posts

- May 2023 (1 post)

- April 2023 (1 post)

- March 2023 (1 post)

- February 2023 (2 posts)

- March 2022 (3 posts)

- March 2021 (1 post)

- August 2020 (1 post)

- May 2019 (1 post)

- April 2018 (1 post)

- November 2017 (1 post)

- April 2017 (1 post)

- November 2016 (1 post)

- September 2016 (1 post)

- August 2016 (1 post)

- January 2014 (2 posts)

- October 2013 (7 posts)

- September 2013 (1 post)

- August 2013 (3 posts)

- June 2013 (3 posts)

- May 2013 (4 posts)

- April 2013 (3 posts)

- March 2013 (9 posts)

- February 2013 (8 posts)