Rudder with filler.

by Dermot Tynan in Microtransat

Posted on Monday, September 23, 2013 at 08:00

This is a quick photograph of the rudder stock once it was filled with a mixture of West System 405 microfibres and West System epoxy. I formed a basic mould out of wood, added "shrink wrap" to prevent the filler from sticking to the mould, dropped in the rudder stock frame (see below) and then poured in the filler. It took around a week to fully harden, and I will sand and paint the finished product.

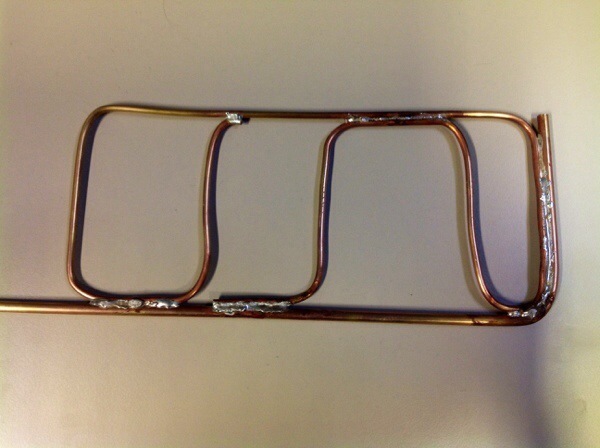

It was formed around a brass stock which you can see here:

The rudder shaft is an 8mm brass rod bent into an 'L' shape. It is reinforced with 4mm brass rod soldered into the above pattern. All of that is then moulded into the finished product.

The biggest concern here is that the rudder shaft will lose traction inside the rudder, due to the torque of the motor against the rudder surface. If that happens, the rudder will swing back and forth with the current. By utilizing an 'L' section and then adding additional reinforcements, the rudder should be prevented from slipping. It also helps that the stepper motor controller has an adjustable current limit, which translates into an adjustable torque limit. The stepper will slip before over-torquing the rudder. That's the plan, anyway.

Search

Upcoming Missions

- Galway Bay Loop, Waiting for Vessel Availability

Recent Posts

- May 2023 (1 post)

- April 2023 (1 post)

- March 2023 (1 post)

- February 2023 (2 posts)

- March 2022 (3 posts)

- March 2021 (1 post)

- August 2020 (1 post)

- May 2019 (1 post)

- April 2018 (1 post)

- November 2017 (1 post)

- April 2017 (1 post)

- November 2016 (1 post)

- September 2016 (1 post)

- August 2016 (1 post)

- January 2014 (2 posts)

- October 2013 (7 posts)

- September 2013 (1 post)

- August 2013 (3 posts)

- June 2013 (3 posts)

- May 2013 (4 posts)

- April 2013 (3 posts)

- March 2013 (9 posts)

- February 2013 (8 posts)