Rudder Movement Test

by Dermot Tynan in Microtransat

Posted on Thursday, April 27, 2017 at 11:10

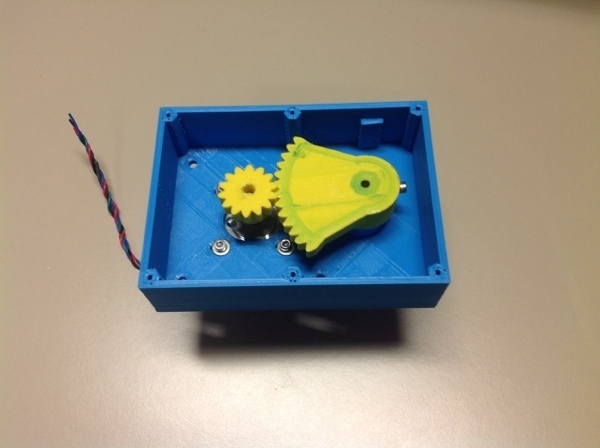

I have uploaded a video (to YouTube) of the rudder mechanism on Hull #1 working from end-stop to end-stop. (Excuse the video quality, I used my phone to record it.)

I connected an Arduino (Mega2560 if you want to know) and a SparkFun stepper controller to the stepper motor which drives the rudder. I wanted to exercise the tiller gears and the rudder shaft for a while. The video shows the rudder swinging from almost completely to Starboard, all the way back to Port.

It actually moves around 160 steps to Starboard and 170 steps back to Port. This is why there's a slight crunching sound, as the main gear hits the stops. I have a zero-sense microswitch which can detect when the rudder has come all the way over to Port, but it isn't connected as yet.

The nice thing about using a stepper motor for controlling the rudder (Rudder box with gears) is that I can current-limit the stepper motor, which provides a sort of torque clutch. If the rudder is trying to push against a hard object, the stepper motor will slip rather than shearing the tiller gear to rudder shaft attachment, or worse. The down side is that the rudder doesn't have a lot of torque. However, it means I also don't have to worry about the stepper motor losing its position and slamming the rudder against the stops. That can happen, but it won't damage anything.

Losing track of where the rudder actually is, isn't a problem because of the zero-sense microswitch. The software can recalibrate the rudder position by bringing it all the way over to the port side until the microswitch acknowledges it has hit the end. From there, it is around 80 step increments to the zero position. I say "around 80" because I still need to accurately calibrate where the rudder-centre position is in relation to the zero stop.

The other aspect of all of this is the PID controller which controls rudder position. Thanks to the I-term of the controller, if the rudder loses sense of where it is, the controller integrates (sums) the error and will continue to apply rudder angle above and beyond what the P-term thinks is reasonable until such time as the desired course is achieved. I will need to remember to clear the integral-error whenever the rudder is recalibrated. Again, this isn't entirely necessary as the error integral will work itself out one way or the other.

Hull #2 is using a worm-gear motor drive for the rudder, which is a different type of design. The advantage of a worm gear is that the rudder won't slip out of position if power is removed from the motor. Mind you, that can also be a bad thing if the rudder is nudged while transporting to the sea. If the worm gear won't budge, then the attachment between the rudder and the rudder shaft will be under heavy torque. Likewise, the gear at the top of the rudder shaft may lose its locking against the shaft.

By way of contrast, a stepper motor consumes power regardless of rudder position.

As of yet, I'm not 100% convinced that the worm-gear mechanism is an improvement. I anticipate that the boat will end up making a lot of small rudder movements, and as a result, the opportunity to disable the motor power will be short-lived. It is possible to dampen the enthusiasm of the rudder worm-gear motor by appropriate tuning of the PID controller and ignoring small course errors. But I suspect over the course of a long navigation, the power saved may end up being negligible. Unfortunately, the loss of an electronic slip-clutch may turn out to be hazardous. Time will tell...

Astute observers will notice that the boat is now a uniform blue colour. The original colour reflected the white of the Polyester resin, with a slight yellowing due to the outer epoxy layer. I painted the entire boat, above and below the water line, in a primer and then a blue marine paint. Naturally, as it's a marine paint, it wasn't cheap. I would have preferred a more obvious colour such as yellow, but it was more a question of what they had in stock in the local Chandlers.

The hull isn't antifouled as I expect this boat (Hull 1) won't spend more than a few days at a time, in the water.

Search

Upcoming Missions

- Galway Bay Loop, Waiting for Vessel Availability

Recent Posts

- May 2023 (1 post)

- April 2023 (1 post)

- March 2023 (1 post)

- February 2023 (2 posts)

- March 2022 (3 posts)

- March 2021 (1 post)

- August 2020 (1 post)

- May 2019 (1 post)

- April 2018 (1 post)

- November 2017 (1 post)

- April 2017 (1 post)

- November 2016 (1 post)

- September 2016 (1 post)

- August 2016 (1 post)

- January 2014 (2 posts)

- October 2013 (7 posts)

- September 2013 (1 post)

- August 2013 (3 posts)

- June 2013 (3 posts)

- May 2013 (4 posts)

- April 2013 (3 posts)

- March 2013 (9 posts)

- February 2013 (8 posts)